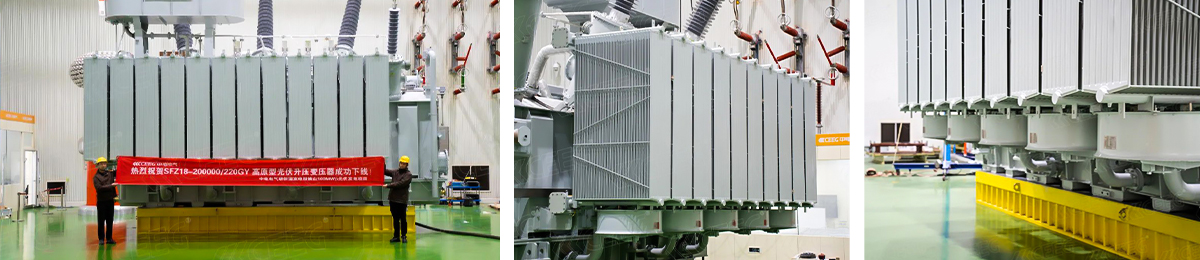

CEEG's main transformer "Big Mac" used in the field of new energy - SFZ18-200000/230/37 plateau photovoltaic power generation boost transformer makes its debut! This is one of the transformer products with a larger single capacity and higher voltage levels developed and supplied by CEEG so far.

In the past few weeks, the Medium and High Voltage Division has gone all out to complete all production processes such as body assembly, coil drying, and finished hanging core of this main transformer. It has successfully passed various inspections and tests in the CNAS laboratory, and the product meets the requirements. New energy efficiency standards and industry requirements.

This product uses advanced materials and processes, has been carefully designed and developed to have higher reliability and excellent durability, and can adapt to application needs in various complex scenarios:

1. Large capacity, low loss, high efficiency

By optimizing the structure, the stray loss of the transformer is reduced, and it meets the third-level energy efficiency requirements of the GB20052-2020 new energy efficiency standard. The operating efficiency of the transformer at full load is as high as 99.72%, effectively reducing the operating cost of the transformer.

2. High overload

Through the core 7-level temperature control technology, the temperature of each part of the transformer is accurately controlled and the emergency overload capacity of the transformer is improved.

3. Low partial discharge

Through optimized design structure and production process, the transformer partial discharge is lower than 50pC.

4. Strong unbalanced load capability

Through the special iron core and balanced winding structure design, it can provide compensation for the user's unbalanced load and meet the user's unbalanced load operation requirements.

5. Intelligent

The operation of the air cooler is intelligently controlled through a dedicated control system, which effectively improves the reliability and economy of the cooling system. The transformer is equipped with online monitoring systems such as oil chromatography to achieve real-time online analysis, diagnosis, and prediction, thereby improving the operational reliability of the transformer.

6. Modular design

The optimized modular design makes the transformer structure easy to install and maintain on-site.

7. Strong resistance to short-circuit

Through short-circuit resistance simulation analysis, the structural design is optimized to ensure that the product meets sudden short-circuit requirements.