The Market for Water-Cooled Transformers

The Market for Water-Cooled Transformers

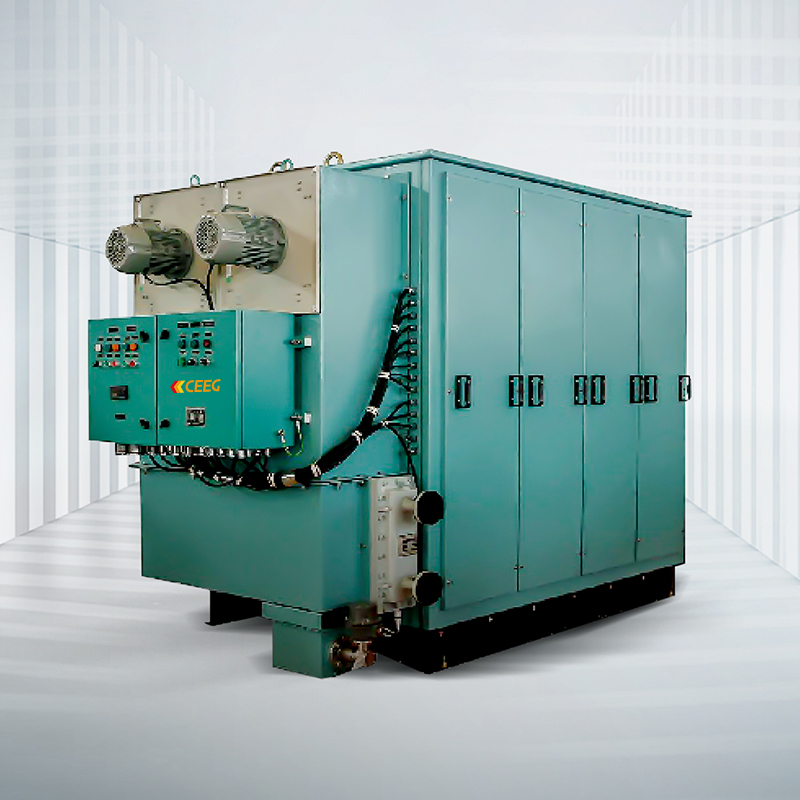

Currently, in the maritime propulsion system, water-cooled transformers are primarily sourced from foreign equipment suppliers, both domestically and internationally. Our company is the first domestic manufacturer to produce water-cooled transformers for marine applications and has accumulated numerous significant achievements in this field.

Development History of CEEG Marine Transformers

In 2006, we commenced trial production of marine transformers and entered the market.

In 2007, our marine and offshore platform transformers underwent product appraisal organized by the Jiangsu Provincial Economic and Trade Commission and the Zhenjiang Municipal Economic and Trade Commission. A panel of experts unanimously acknowledged that our products possessed exceptional characteristics, including strong overload capacity, low losses, low noise, compact size, lightweight, and easy installation. The main performance indicators had already reached the leading domestic level.

In 2008, we initiated research and development on 12-pulse and 24-pulse rectifier transformers and entered the market.

In 2009, we commenced research and development on marine water-cooled transformers and secured our first batch of orders for eight units of 1600kVA transformers in 2010.

Performance Characteristics of Water-Cooled Transformers

Key Product Features: DuPont insulation system, "three-proof" process treatment, VPI vacuum impregnation treatment,electronic "three-proof" coating process,and more.

1. Ambient Temperature: Maximum Temperature: +40°C, Minimum Temperature: -30°C, Maximum Daily Average Temperature: +20°C,

2. Maximum Annual Average Temperature: +30°C.

3. Altitude: ≤1000m.

4. Maximum Relative Humidity (Air Temperature +25°C) should not exceed 95%.

Our transformer production facility covers an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers. We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane.

Our transformer production facility covers an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers. We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane.

.jpg!webp)

.jpg!webp)

.jpg!webp)

.jpg!webp)